Sanitary Distribution Piping

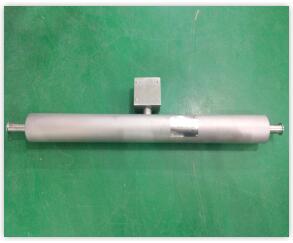

GMP SaniHeater

Product Details

Product Details

GMP SaniHeater

An Application of Electric Piping Heater in WFI Distribution Loop Temperature Compensation

Introduction

The GMP SaniHeater is a temperature compensation type electric piping heater, which is an innovative product for sanitary fluid non contact heating, it is applicable for maintaining the temperature for WFI distribution loop or heating for PW user points, especially during the holidays or night, when the plant industrial steam is not available, the GMP SaniHeater can be used to maintain the WFI loop temperature. It is completely GMP complied and also cost effective.

Product Features:

a) Non Contact Structure design to avoid cross contamination

b) Innovative heater structure, self correction power output, rapid temperature increase, when the temperature is close to set temperature, heater will decrease power automatically to save energy.

c) special heat transfer structure and material to increase heat transfer efficiency.

d) Heating Temperature settable, to ensure accurate temperature control

e) Electric leakage Proof Design to ensure safety.

f) Easy for installation and maintenance.

g) Full set of validation documents, including MOC report.

Parameters

Model | Power (Kw) | Voltage (V) | Temperature (℃) | Pressure (MPa) | Flow Rate (T/hr) | Connection |

EHT-1-40 | 6 | AC220 | 135 | 1.0 | 3.5 | DN40 Tri Clamp |

EHT-1-50 | 9 | AC220 | 135 | 1.0 | 5.0 | DN50 Tri Clamp |

Comparison between GMP SaniHeater and traditional heating methods.

1. Regulations For WFI Distribution Loop are as the following:

Systems that operate and are maintained at elevated temperatures, in the range of 70–80 °C, are generally less susceptible to microbiological contamination than systems that are maintained at lower temperatures. (WHO)

China cGMP and European Pharmacopeia requests the WFI to be circulated above 70℃

FDA requests WFI to be maintained above 85℃

2. Traditional methods of maintaining the temperature

traditional methods as the following are adopted to maintain temperature of WFI distribution loop:

the original temperature is determined by Multi Effect Still, usually the Multi Effect Still product WFI at temperature >95℃

Heat Exchangers are usually used for heating or maintain the temperature, and the heating medium is industrial steam.

however, once the WFI Still stops producing water (machine shutdown in the night), or to prevent from the red rust, the WFI is cooled to specified temperature range and maintain circulated, during the storage and circulation, heat loss will decrease the loop temperature. usually a heat exchanger or jacketed vessel is designed to maintain the temperature, under this design, the boiled steam shall be supplied all the time, even during the plant shutdown period or holiday, and the boiler system has also to be well maintained to avoid fault running.

3. Saniheater by electric heating and insulation

Saniheater is installed in the distribution loop by means of electric heating and heat transferring, heat loss during storage and loop circulation could be compensated, even there is no industry steam supply, the temperature could be maintained.

Cost Calculation for steam heating and electric heating

For Steam Heating:

Centralized Steam Pipeline: Cost for 1T Steam is usually 20-50 Dollars, and heat loss of pipe line is 5-10%.

Plant Boiler, by Diesel(or Nature Gas), consumption of diesel is 70-80L/h (or nature gas at 40 m3), cost is 1 dollar/L(0.75dollar/m3), total cost is around 70 dollars (30 dollars).

For Electric Heating:

For DN 40 pipeline, at 1m/s velocity and 3.5T/hr circulation rate, the temperature drop 1℃ at each hour, total heat loss is 3500kcal/hr, which equals 4kw electric heating. For 70-80% heat efficiency, the design power is 6kw. At cost of around 0.33 dollars/kw, total cost is only 2 dollars/h.

Item | Steam Heating | Electric Heating |

Power Consumption /hour | Diesel 70L(Nature gas 40m3) | Electric power 6kw |

Unit Price | 1dollar (0.75 dollars) | 0.33 dollar |

Total cost | 70 dollars (30 dollars) | 2 dollars |

So from the above calculation, the electric heating is more cost effective.

Standard Configuration:

SaniHeater, EHT-1-40, AC220V/50Hz/6KW/DN40 Tri Clamp, MOC SS316L

SaniHeater, EHT-1-50, AC220V/50Hz/9KW/DN50 Tri Clamp, MOC SS316L

Option:

Temperature sensor, PT100, Tri Clamp, MOC SS316L

Temperature Controller: PXR Series

Site Control Cabinet, 500(H)×400(W)×250(D), including RCD (residual current device), breaker, solid relay etc

Clients

Copyright © 2020 - AA Pharmatech® Limited